| .. | ||

| images | ||

| README.md | ||

Note: This is copied from a 2018 EEVBlog post by Luiz Renault for posterity. https://www.eevblog.com/forum/manufacture/neoden-tm245p-teardown-and-upgrade/

post

Hi.

Tired of the painful process to setup the Neoden TM245P Pick and Place, I decided to make a mod to OpenPNP to export a CSV file compatible with the Neoden machine.

This way I can reuse component database and check if required components are present or need to be installed on free feeders.

But that isn't enough. I really want to install a vision system and make it compatible with OpenPNP to control the machine.

Today I opened the bottom plate and collected some information to check if the upgrade is possible using the original electronics.

Here I share my findings...

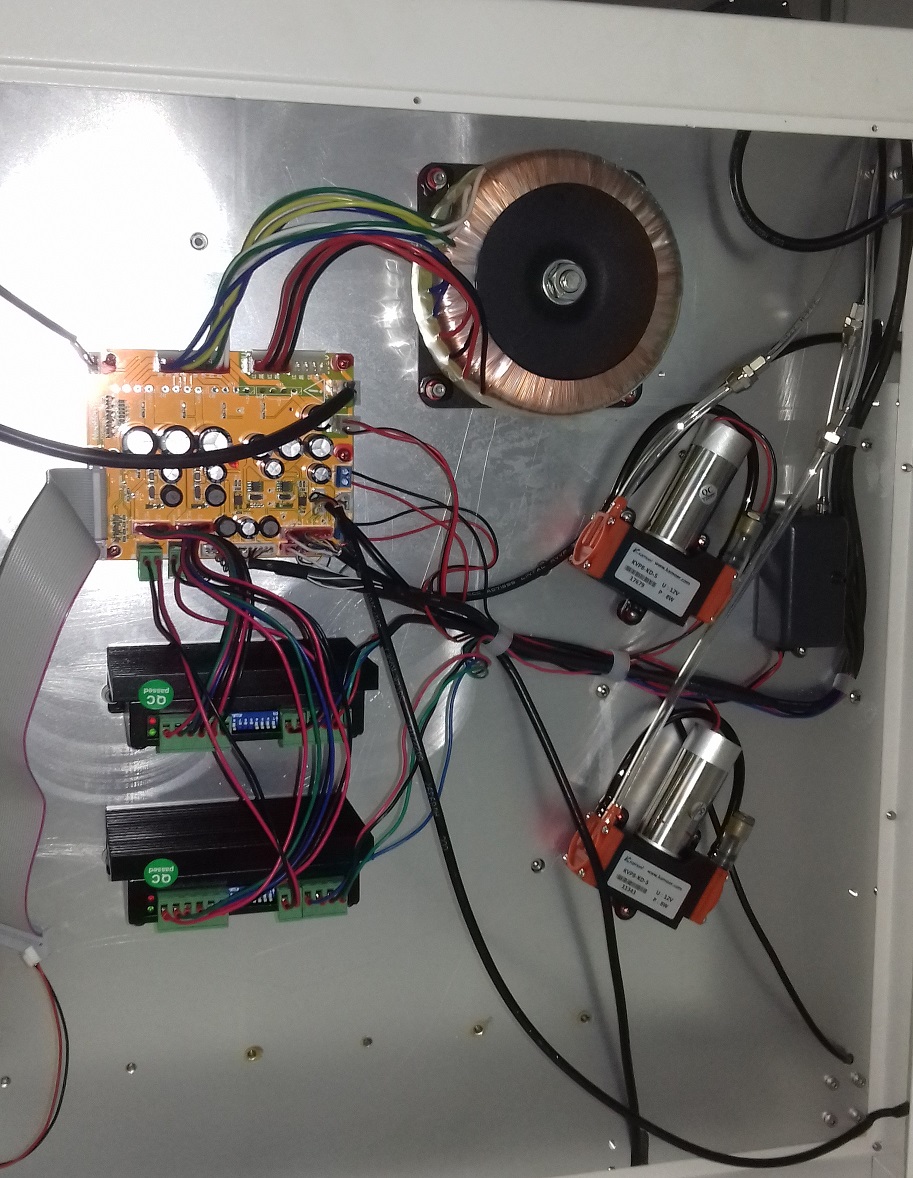

The guts of the TM245P consists of:

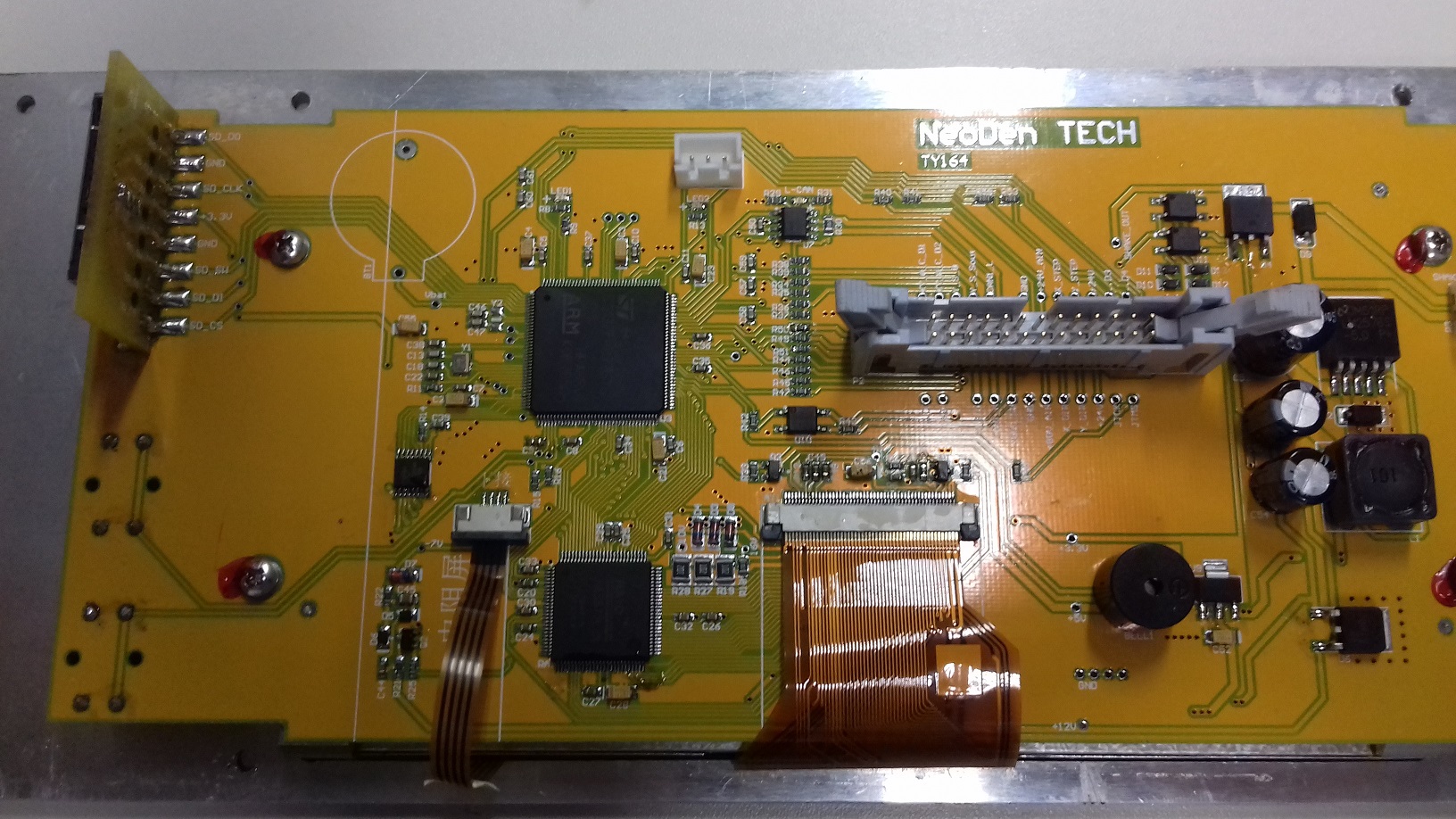

a motherboard (model TY164) with TFT LCD and resistive touch

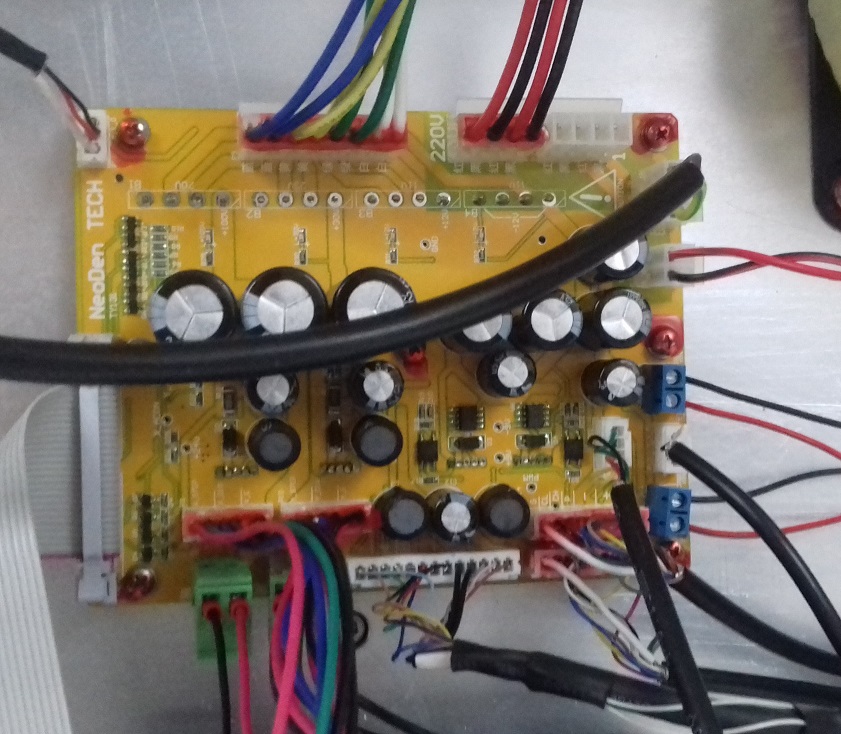

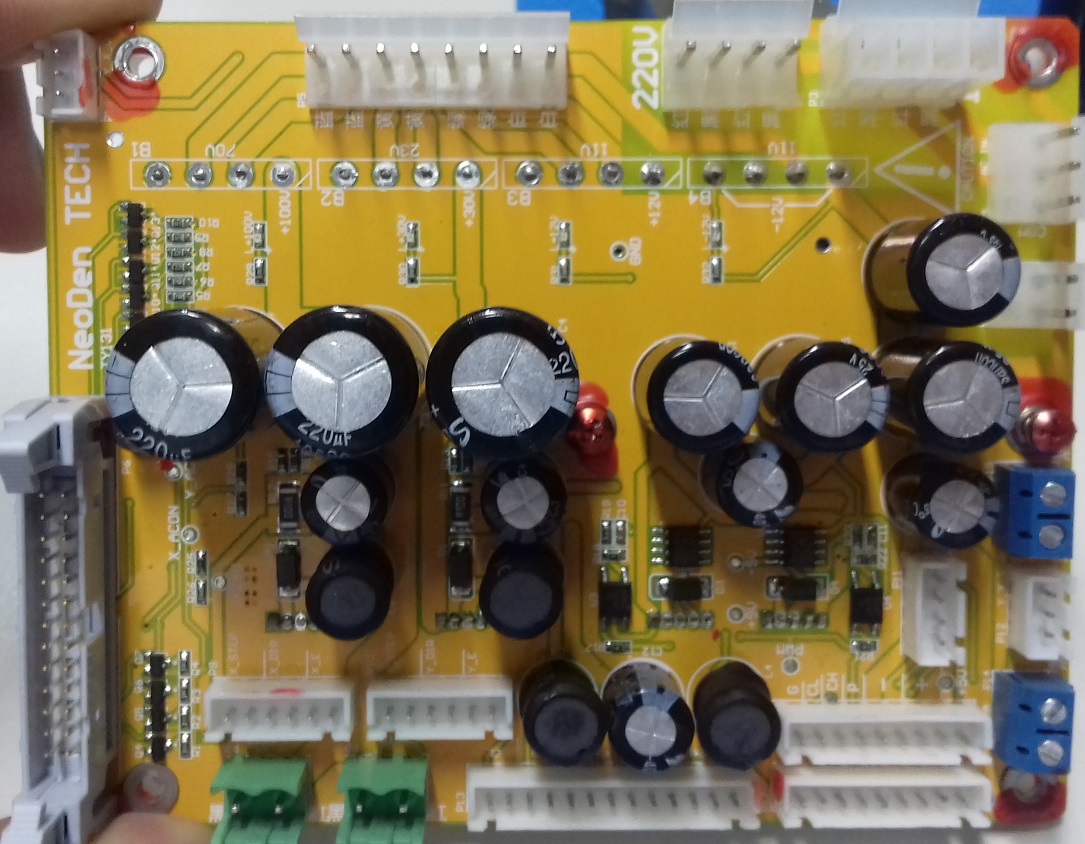

a power supply and control board (model TY131)

two microstep driver

two vacuum pumps

one air blower

a transformer

The motherboard have a STM32F407ZGT6 and a RA8875L3N TFT LCD Controller. The SD card slot can be seen on the left side of the board. At the center there is a 26 pin IDC connector that goes to the power supply and control board. On the top a 3 pin SWD connector and on the right side a 2 pin connector that powers the vibration feeder can be seen.

The board uses as power supply 24V that comes from the power supply and control board. There is a 5V step down regulator (LM2576S-5.0) that supplies the uC through a 3.3V Linear reg. The 5V rail are sent back to the power supply and control board.

This is the microstep driver:

The power supply and control board have 4 diode bridge rectifiers (GBU808 on bottom layer) with +100V, +30V, +12V and -12V labels.

There are four step down regulators (LM2576T-ADJ): +30V->+24V, +30V->+24V, +12V->+9V e -12V->-9V

And the following connectors:

P1 -> Transformer (label 220V)

P2 -> air blower (connected to AC input)

P3 -> Transformer (label 110V)

P4 -> AC input and on/off switch

P5 -> Transformer taps labeled 70V, 23V, 11V, 11V

P6 -> To motherboard

P7 -> Power Supply to step controller X axis (connected to 100V labeled line)

P8 -> Power Supply to step controller Y axis (connected to 100V labeled line)

P9 -> X axis step controller signals (EN, DIR, STEP)

P10 -> Y axis step controller signals (EN, DIR, STEP)

P11 -> To DB9 connector at the back of the equipment (CAN-H CAN-L JTMS e JTCK

P12 -> Endstop Y axis switch

P13 -> Pick and place head

P14 -> Vacuum Pump A

P15 -> Vacuum Pump B

P16 -> Endstop / origin Y axis switch

P17 -> Feeder block 1

P18 -> Feeder block 2

The feeders and the head are controlled through a CAN bus connection. The same bus goes to the back DB9 connector.

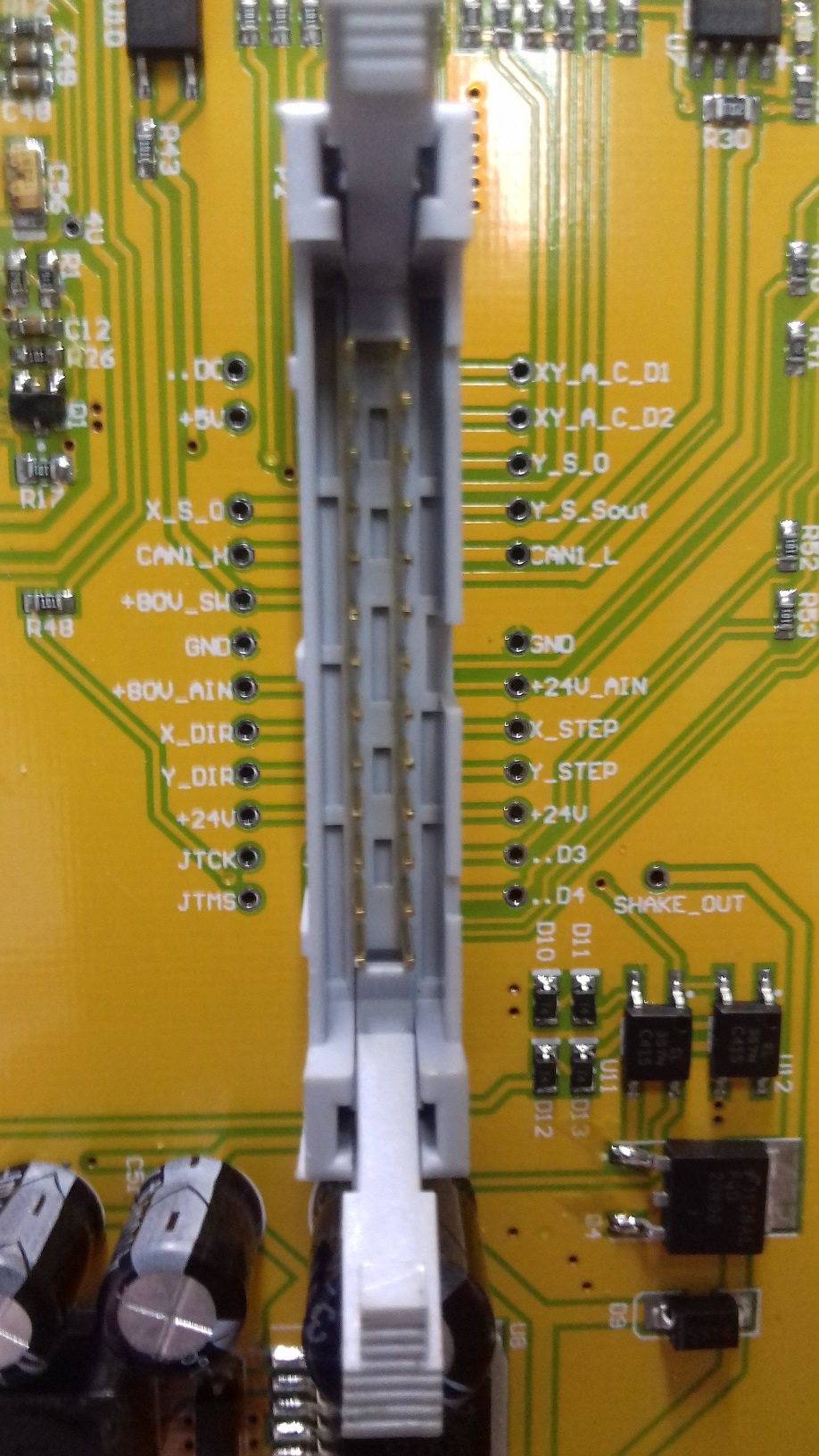

This is the 26 pin connector pinout from the motherboard:

I tried to read the firmware but the uC have Level 1 Read Protection.

The next step is to log the CAN communication while sending simple commands using the equipment GUI.

Then I will check if the X and Y axis can be controlled through CAN messages.

Does anybody have the CAN message specification?

Anybody tried to mod this machine?

Best Regards,

Luiz Renault

Hi today I placed a scope on the CAN_H and CAN_L signals on the DB9 back connector.

But they are too noisy to be useful and I had open the Pick and Place head and monitor on the inner (uC) side of the CAN transceiver (SN65HVD230).

I assumed a bit rate 512 kbit/s because the smallest pulse length.

But the oscilloscope wasn't able to decode it. The problem is that the CAN bit stuffing is not present.

Does anyone have any clue?

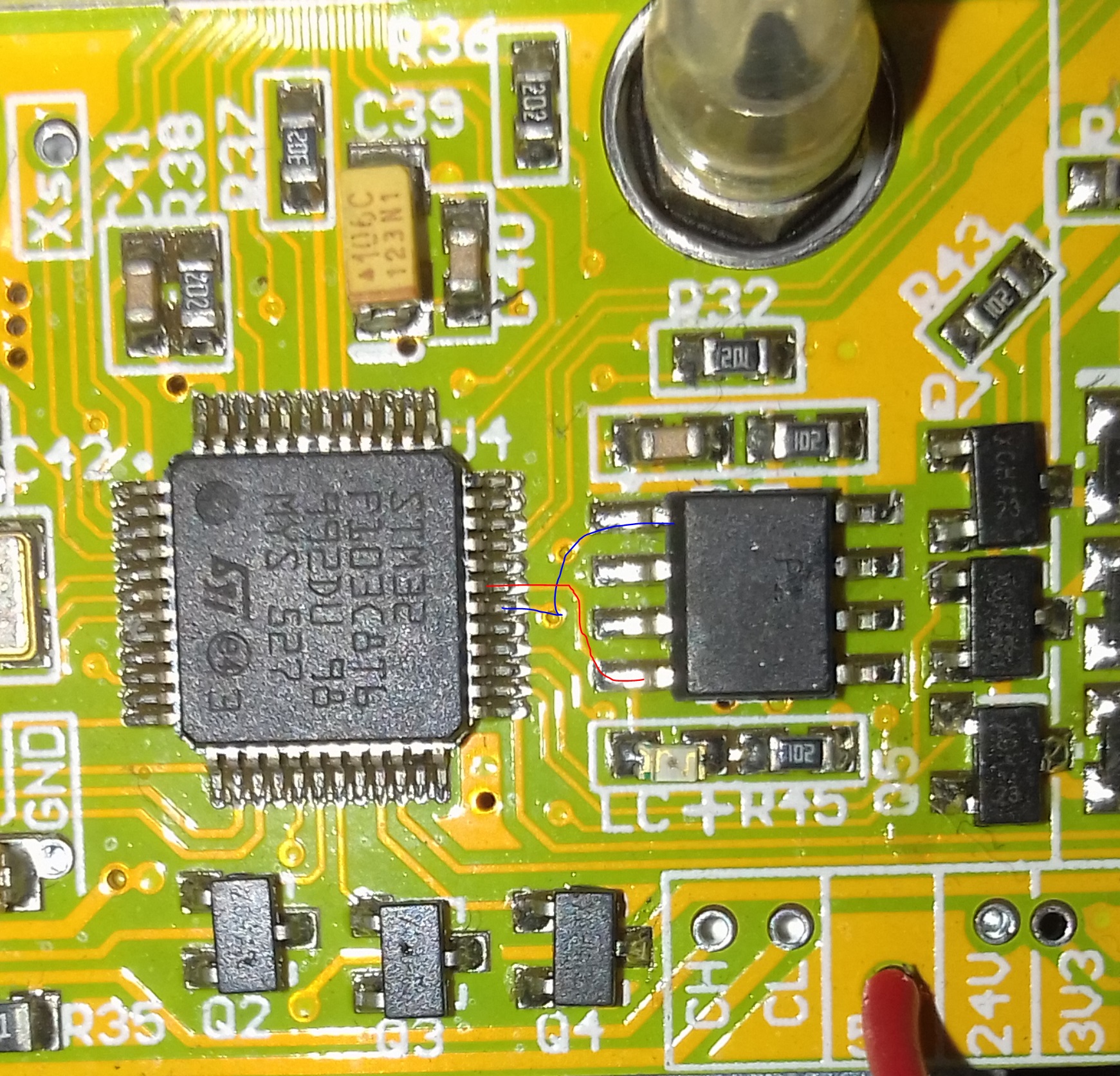

Although it uses a CAN transceiver, I could see on the Placement Head board that the CAN_TX and CAN_RX signals were connected to the USART signals of the STM32F103C8 (PA9 and PA10).

Then I was able to decode de USART 512kbit/s signal. It uses a binary format.